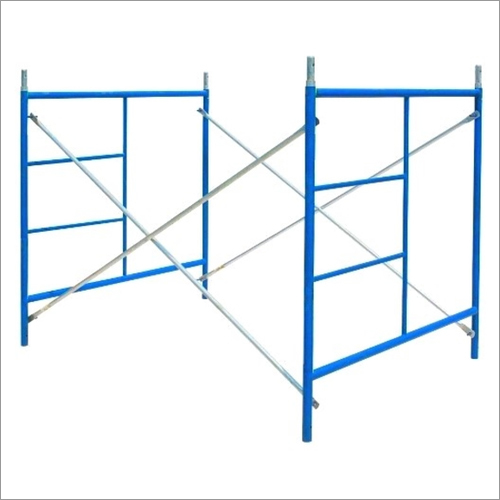

MS Scaffolding Frames

MOQ : 20 Units

MS Scaffolding Frames Specification

- Technique

- Forged

- Features

- High Durability, Corrosion Resistant, High Strength

- Color

- Blue, Red, or customized

- Constitute

- Steel Tubes Assembled

- Weight

- Approx. 15-25 kg/frame

- Pin

- Included for joining frames

- Sleeve size

- 60 mm 70 mm

- Prop Head

- U Head/J Head as per usage

- Product Type

- Scaffolding Frame

- Material

- Steel

- Components

- Main Frames, Cross Braces, Coupling Pins, Base Plates

- Diameter

- 48.3 mm

- Width

- 1219 mm (4 ft) or as per requirement

- Length

- 1829 mm (6 ft) or as per requirement

- Height

- 1219 mm (4 ft) or customizable

- Thickness

- 2.5 mm 3 mm

- Platform Loading Capacity

- Up to 200 kg/m2

- Surface Treatment

- Painted or Galvanized

- Application

- Construction

- Size

- Standard and custom sizes

MS Scaffolding Frames Trade Information

- Minimum Order Quantity

- 20 Units

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 20 Units Per Day

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About MS Scaffolding Frames

We believe that success is not a point, its a series of process that includes all the advance developments and thus, we upgrade our range of MS Scaffolding Frames at regular intervals. We are the famous manufacturer of this MS Scaffolding Frames in the entire industry. Depending upon the requirements of our customers, we make available for them a wide range of MS Scaffolding Frames in different specifications and capacities to choose from. They are widely used for mixing chanachur, snacks and spice.

Product details

| Finish | Paint Coated |

| Type | H Frame |

| Surface Type | Color Galvanized |

| Material | Stainless Steel |

| Brand | Esquire |

| Color | Blue |

| Usage/Application | Construction |

Exceptional Strength and Durability

Manufactured from forged steel tubes and finished with painted or galvanized coatings, our scaffolding frames stand up to rigorous site demands. Each main frame weighs approximately 15 to 25 kg, with a robust frame thickness of 2.5 mm to 3 mm. Compliant with stringent IS 2750 / EN 12810 standards, the frames exhibit impressive resistance to corrosion and long-term durability, making them a wise choice for both large and small projects.

Advanced Safety and Compliance

Safety sits at the core of our scaffolding frames, which are fully compliant with ISI regulations for construction. The frames use a pin and lock system for secure assembly, and U Head/J Head props for added stability. With proper maintenance, the lifespan extends beyond 10 years. Our products undergo strict quality checks to guarantee peace of mind on every site.

Versatile Application and Easy Assembly

Designed for hassle-free installation, each set features quick lock systems and handy accessories like joint pins, bracing pipes, and locks. The frames modular designoffering H Frame or Ladder variantscaters to a wide range of commercial spaces and project requirements. Available in standard and customized sizes, our scaffolding adapts to specific site dimensions for optimal support.

FAQs of MS Scaffolding Frames:

Q: How is the MS scaffolding frame assembled on-site?

A: The MS scaffolding frame features a pin and lock system for rapid and secure assembly. Simply connect the H Frame or Ladder Frame components using the included pins and locks, ensuring all accessories such as joint pins, base plates, and bracing pipes are properly installed according to your layout. The quick lock system significantly reduces setup time.Q: What are the primary safety features of your scaffolding frames?

A: Our frames are manufactured to ISI regulations, using robust steel construction forged with CO2 arc welding. The quick lock system and stable pin connections minimize movement, while corrosion-resistant surfaces enhance longevity. Additionally, each frame supports up to 2500 kg per set, ensuring reliable structural support during construction activities.Q: When should the scaffolding frames be inspected during their shelf life?

A: It is recommended to inspect the scaffolding frames before each use, after assembly, and periodically throughout their lifespanespecially after exposure to harsh environmental conditions. With proper maintenance, these frames can last over 10 years; regular inspections help guarantee ongoing safety and performance.Q: Where can these scaffolding frames be used?

A: These scaffolding frames are ideal for construction projects across India, suitable for commercial, residential, and industrial sites. Their customizable size and robust loading capacity make them versatile for both large-scale infrastructure and smaller builds.Q: What customization options are available for scaffolding frames?

A: We offer customizations in frame size, width, height, color (blue, red, or as requested), and packaging. You can also tailor the configuration, including platform loading capacity and sleeve sizes to suit specific project demands. Contact us with your requirements for a tailored solution.Q: How does the surface treatment enhance the scaffoldings durability?

A: Each frame receives either a painted or galvanized finish, providing a barrier against corrosion and harsh weather effects. This surface treatment ensures the scaffolding remains structurally sound over years of use, especially in demanding outdoor environments.Q: What are the main benefits of using your MS scaffolding frames for construction?

A: Our MS scaffolding frames offer high load capacity, quick assembly, superior durability, compliance with international safety standards, and adaptability to diverse project requirements. They also include essential accessories, customizable sizing, and a long service lifedelivering both safety and operational efficiency on construction sites.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese