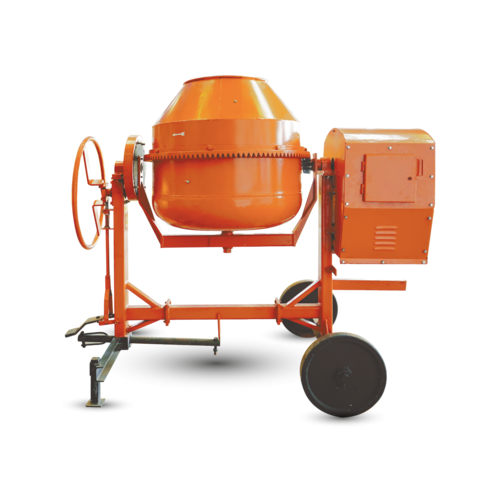

MS Hand Fed Concrete Mixer

MS Hand Fed Concrete Mixer Specification

- Product Type

- MS Hand Fed Concrete Mixer

- General Use

- Industrial , Construction

- Material

- Steel

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Feature

- Long Lasting Service

- Color

- Orange

MS Hand Fed Concrete Mixer Trade Information

- Minimum Order Quantity

- 20 Units

- Supply Ability

- 20 Units Per Day

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About MS Hand Fed Concrete Mixer

Product details

| Material of Construction | Stainless steel |

| Surface Treatment | Galvanized |

| Brand | Esquire |

| Automatic Grade | Automatic |

| Power Source | Diesel Engine |

| Portable (Y/N) | Yes |

Specification

| Technical Data | 7/5 Cubic ft | 10/7 Cubic ft | 14/10 Cubic ft |

| Capacity ( Unmixed ) | 200 Liters | 300 Liters | 400 Liters |

| Capacity (Mixed ) | 150 Liters | 200 Liters | 300 Liters |

| Power (Diesel Engine) | 6 HP | 6 HP | 6 HP |

| Power (Electrical Motor) | 3 HP | 5 HP | 5 HP |

| Output | 3.5 Cubic m/hr | 4.5 Cubic m/hr | 5.5 Cubic m/hr |

Robust Steel Construction

Engineered from high-grade steel, the MS Hand Fed Concrete Mixer guarantees reliability in challenging industrial and construction environments. Its enduring build ensures resistance to wear and tear, providing great value over extended periods of use.

User-Friendly Manual Operation

This concrete mixer features a simple manual control system, making it accessible for operators without advanced training. The lack of computerized components reduces potential breakdowns and facilitates hassle-free operation and maintenance on site.

FAQs of MS Hand Fed Concrete Mixer:

Q: How is the MS Hand Fed Concrete Mixer operated?

A: The mixer is operated manually, requiring an operator to hand-feed the materials and control its functions without the use of computerized systems.Q: What types of projects can this concrete mixer be used for?

A: It is ideal for industrial and construction applications, including small to mid-scale building sites where reliability and easy maintenance are prioritized.Q: When is it beneficial to use a hand fed, manually controlled concrete mixer?

A: This mixer is especially advantageous in scenarios where automated or computerized machinery is impractical or unavailable due to site conditions or resource constraints.Q: Where is this concrete mixer manufactured and supplied?

A: The MS Hand Fed Concrete Mixer is manufactured, supplied, and wholesaled in India, ensuring accessibility and efficient distribution within the country.Q: What is the process of using this concrete mixer on-site?

A: To use, operators manually load the mixer with relevant materials, engage the manual controls to mix, and monitor the process until the concrete reaches the desired consistency.Q: What are the main benefits of choosing this model over automatic or computerized mixers?

A: Key benefits include long-lasting service, straightforward operation, lower maintenance costs, and reliable performance in locations with limited access to advanced technology.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Mixer Category

Hydraulic Hopper Concrete Mixer

Price Range 100000.00 - 500000.00 INR / Unit

Minimum Order Quantity : 20 Units

Color : Orange

Type : Cement Mixer

Automatic : Yes

Reversible Mini Concrete Mixer Machine

Price 500000.0 INR / Number

Minimum Order Quantity : 20

Color : Orange

Type : Cement Mixer

Automatic : Yes

ELEMENTO 3.0

Price 95000 INR / Number

Price Range 87000.00 - 105000.00 INR / Number

Minimum Order Quantity : 1 Piece

Color : Orange

Type : Other, Hydraulic Car Lift

Automatic : Yes

Hand Fed Concrete Mixer

Price Range 100000.00 - 500000.00 INR / Unit

Minimum Order Quantity : 20 Units

Color : Orange

Type : Cement Mixer

Automatic : Yes

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese