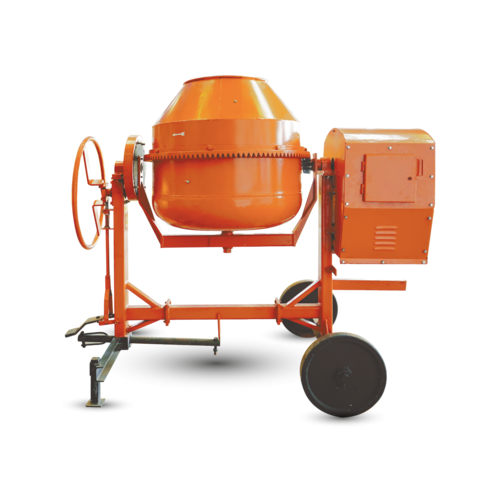

Hydraulic Concrete Mixer

Hydraulic Concrete Mixer Specification

- Motor Power

- 5 Horsepower (HP)

- Product Type

- Hydraulic Concrete Mixer

- General Use

- Industrial , Construction

- Type

- Cement Mixer

- Computerized

- No

- Automatic

- Yes

- Control System

- Manual

- Color

- Orange

- Warranty

- 6 MONTHS

Hydraulic Concrete Mixer Trade Information

- Minimum Order Quantity

- 20 Units

- FOB Port

- GUJARAT

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 20 Units Per Day

- Delivery Time

- 7 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Industrial standard packing, plastic wrap.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- MSME registered company, ISO 9001:2015 certified

About Hydraulic Concrete Mixer

Product details

|

Calibrated Water Tank |

Optional |

|

Capacity (Mixed ) |

200 Liters |

|

Capacity (Unmixed) |

300 Liters |

|

Dual Drive Arrangement |

Optional |

|

Output |

8 Cubic m/hr |

|

Prime Motor (Diesel Engine) |

6 HP |

|

Prime Motor (Electrical Motor) |

5 HP |

|

Skip (Loading Hopper) |

Hydraulic Operated |

|

Technical Data |

10/7 Cubic ft |

|

Brand |

Esquire |

|

Automatic Grade |

Automatic |

Superior Automation for Seamless Mixing

The fully automatic hydraulic system in this concrete mixer ensures a hassle-free operation and uniform mixing quality. With just the push of a button, the machine blends concrete ingredients efficiently, significantly cutting down on manual effort and time, allowing workers to concentrate on other critical tasks during construction.

Built to Last with Stainless Steel Durability

Engineered from high-grade stainless steel, our mixer is resistant to rust, corrosion, and wear. This construction guarantees extended service life even in harsh industrial conditions, making it a cost-effective investment for businesses seeking long-term reliability in their equipment.

FAQs of Hydraulic Concrete Mixer:

Q: How does the hydraulic system in the concrete mixer improve the mixing process?

A: The hydraulic mechanism automates the mixing drums rotation and tilting, ensuring thorough and consistent blending of concrete components. This reduces manual intervention and enhances productivity on-site.Q: What are the primary benefits of using a stainless steel automatic concrete mixer for industrial projects?

A: Stainless steel construction provides outstanding durability and resistance to corrosion, while the automatic operation streamlines workflow, reduces labor costs, and increases overall efficiency during construction.Q: When is this hydraulic concrete mixer most beneficial for construction projects?

A: This mixer is especially advantageous for large-scale or continuous concrete pouring tasks, where speed, consistency, and reduced labor are crucial to meet deadlines and quality standards.Q: Where can the orange hydraulic concrete mixer be sourced in India?

A: This product is available directly from reputable manufacturers, suppliers, and wholesalers across India, ensuring easy procurement and prompt after-sales support wherever your project is located.Q: What is the general process for operating this automatic concrete mixer?

A: Operators simply load materials into the drum, engage the automated control system, and allow the hydraulic mechanism to mix and discharge the concrete, ensuring efficient and homogeneous results.Q: How does usage of this concrete mixer benefit construction contractors?

A: Contractors benefit from quicker mixing times, reliability under heavy use, reduced need for manual labor, and improved safety, all contributing to higher productivity and lower operating costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Mixer Category

Reversible Mini Concrete Mixer Machine

Price 500000.0 INR / Number

Minimum Order Quantity : 20

Automatic : Yes

Computerized : No

Material : Steel

ELEMENTO 3.0

Price 95000 INR / Number

Price Range 87000.00 - 105000.00 INR / Number

Minimum Order Quantity : 1 Piece

Automatic : Yes

Computerized : No

Material : Steel

Hand Fed Concrete Mixer

Price Range 100000.00 - 500000.00 INR / Unit

Minimum Order Quantity : 20 Units

Automatic : Yes

Computerized : No

Material : Steel

Mechanical Concrete Mixer

Price Range 100000.00 - 500000.00 INR / Unit

Minimum Order Quantity : 20 Units

Automatic : Yes

Computerized : No

Material : Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese