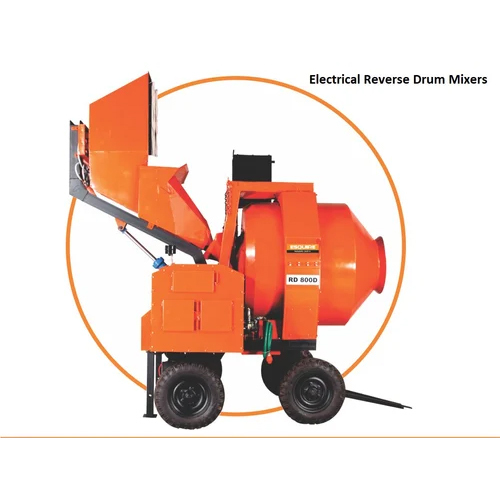

Electrical Reverse Drum Mixer

Electrical Reverse Drum Mixer Specification

- Equipment Type

- Electrical Reverse Drum Mixer

- Features

- High mixing efficiency, Easy mobility

- Motor Type

- Electric motor (Copper winding)

- Belt Type

- V-Belt Driven

- Rotation Type

- Reverse Drum Mixing

- Control System

- Manual/Electric Switch

- Usage

- Industrial

- Condition

- New

- Product Type

- Electrical Reverse Drum Mixer

- Color

- Orange

- Power Source

- Electric

- Power Consumption

- 3 HP - 5 HP (Typical) Horsepower (HP)

- Voltage

- 415V (Three Phase) Volt (v)

- Framework

- Rugged steel construction

- Weight

- 1100 kg (Approx.)

- Drum Capacity

- 500 L (Approx.)

- Output per hour

- 10-12 Cubic meter/hr

- Drum Speed

- 20-22 RPM

- Dimensions

- Approx. 2700 mm x 1800 mm x 2550 mm

- Drum Material

- Mild Steel

- Number of Wheels

- 4

- Mixing Capacity

- 400-500 kg per batch

- Application

- Concrete Mixing

Electrical Reverse Drum Mixer Trade Information

- Minimum Order Quantity

- 20 Units

- Supply Ability

- 20 Units Per Day

- Delivery Time

- 7 Days

About Electrical Reverse Drum Mixer

Product details

|

Color |

Orange |

|

Finish |

Paint Coated |

|

Surface Treatment |

Galvanized |

|

Automation Grade |

Automatic |

|

Brand |

Esquire |

|

Type of the drum mixer |

Reverse Drum Mixer |

Specification

|

Model |

RD-400E |

RD-600E |

|

|

A |

Overall length |

4100 |

4750 |

|

B |

Overall width |

1950 |

1990 |

|

C |

Overall height |

2780 |

2780 |

|

D |

Discharge height |

1350 |

1550 |

|

E |

Feeding height |

880 |

920 |

|

Model |

RD - 400E |

RD-600E |

|

Unmixed capacity |

600 ltr. |

800 LTR. |

|

Mixed capacity |

400 ltr. |

600 LTR. |

|

Discharge height |

1300 mm |

|

|

Production rate |

8 to10 cu. mt. /hr. (20 to 25 batches/hr.) |

12 to15 cu. mt. /hr. (20 to 25 batches/hr.) |

|

Drive |

Electric motor 10 hp/1440 rpm. |

Electric motor 12.5 hp/1440 rpm. |

|

Weight batching |

Digital |

|

|

No. of hopper bins |

1/2/3/4 Bins. |

|

|

Water tank |

90 liters capacity |

120 liters capacity |

|

Water pump |

Self-priming mono-set type |

|

Efficient and Durable Construction Mixer

Engineered for industrial use, this reverse drum mixer features a high-capacity mild steel drum and a sturdy chassis. The heavy-duty build ensures long-lasting performance even under challenging conditions, and the V-belt driven mechanism is designed for efficient power transfer. Its orange color and compact footprint (2700 mm x 1800 mm x 2550 mm) make it easily identifiable and practical for urban or rural projects.

Reliable Power and Control

Equipped with a 415V, three-phase electric motor (3 HP 5 HP), the mixer operates smoothly and efficiently. Users can select between manual and electric switch controls for convenient operation. The advanced motor design with copper windings ensures reliable performance, while the mixers sturdy frame and heavy cast iron wheels facilitate easy positioning on construction sites.

FAQs of Electrical Reverse Drum Mixer:

Q: How does the reverse drum mixer improve concrete mixing efficiency?

A: The reverse drum mixer uses counter-rotating drum action to thoroughly blend concrete components, resulting in a more homogeneous mix. The electric motor delivers consistent speed (20-22 RPM), ensuring even mixing and reduced batch times, which enhances overall productivity.Q: What is the recommended usage process for this mixer?

A: To operate, load the drum with aggregates, cement, and water, then engage the mixer using the manual or electric switch. Allow the drum to complete several rotations (forward for mixing, reverse for discharge) until the concrete achieves the desired consistency. The mixers easy mobility enables positioning close to the pour site for convenience.Q: When should I choose an electrical reverse drum mixer over a regular mixer?

A: This type of mixer is ideal when high mixing efficiency and large batch output are required. If you need consistent concrete quality, high-volume production (10-12 cubic meters per hour), and ease of use with electric power, the electrical reverse drum mixer is preferable to standard mixers.Q: Where can this mixer be ideally used?

A: The mixer is suited for construction sites, precast concrete operations, and industrial plants needing reliable and efficient concrete mixing. Its durable wheels and compact size make it adaptable to both indoor and outdoor use, accommodating various job site conditions.Q: What are the main benefits of using a copper-wound electric motor in this mixer?

A: Copper winding in the motor increases energy efficiency, reduces heat buildup, and provides superior durability. This translates to longer operational life and reliable, consistent power for uninterrupted mixing sessions on the job site.Q: How does the V-belt drive contribute to the mixers operation?

A: The V-belt drive system ensures efficient transmission of power from the motor to the drum. It reduces slippage, offers smoother operation, and requires minimal maintenance, which helps maintain continuous, trouble-free mixing throughout the project lifecycle.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Reverse Drum Mixer Category

Automatic Reverse Drum Mixer

Price Range 100000.00 - 500000.00 INR / Unit

Minimum Order Quantity : 20 Units

Color : Orange

Power Source : Electric

Condition : New

Usage : Industrial , Construction

Diesel Reverse Drum Mixer

Price Range 100000.00 - 500000.00 INR / Unit

Minimum Order Quantity : 20 Units

Color : Orange

Power Source : Diesel

Condition : New

Usage : Industrial , Construction

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese